Design of Mechanical Systems

Sort n' Play

Team Duct Tape's Sort n' Play is a machine capable of sorting Lego bricks based on what color they are. The machine starts off by dumping lego bricks into a hopper. The hopper leads down to an augur that slowly feeds the lego bricks out onto a conveyor belt. The conveyor belt is tilted, in order to draw the lego bricks to one side, and has intermittent ramps to ensure that the legos reach the end of the belt one brick at a time. The end of the belt houses the solor sensor. After passing through the color sensor, the pieces fall into a bin separated into sections for each color.

Concept Generation

Three Needs

The Team deteremined three problems that are common amongst the group. The selected ideas were: a process to clean up Lego bricks more easily, a need for a machine to clean one single utensil in a matter of milliseconds, and a way to increase desk space at any desk.

Problem

"How can we facilitate the clean-up of Lego bricks to aid both children and adults?" - This question became the problem that was settled upon after socratic seminar discussion and the construction of FRSARC charts.

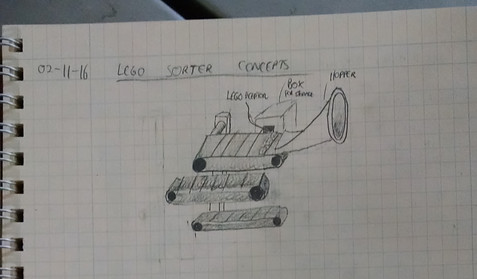

Sketches and Sketch Models

The Team immediately set to drawing sketches and building sketch models to determine how the project would look and feel in the users' hands.

Construction

Conveyor Belt

The ramps seen along the conveyor belt are actually part of an industrial design, called the Chicane Conveyor. This is a commonly used practice in industry when a cluster of components needs to be arranged in a one-by-one fashion. This was used to arrange the Lego bricks in a line for the Color sensor to read. Another unique feature about the conveyor belt is that it is tilted 45 degrees to use gravity to pull the Lego bricks closer to one side. This both decreases the distance between the bricks and facilitates the single file line organization. The axel driving the belt is connected directly to an 8 RPM molon motor. A sprocket on the axel combined with a timing belt drives the augur shaft, thus the augur, in the hopper system.

The Hopper

The hopper system accepts a large amount of Lego bricks, but has a small acceptor hole to prevent small children’s hands from finding their way to the augur. The bricks fall in and slide down a series of ramps to facilitate their flow into the augur. The augur rotates at a speed of 5 RPM. This allows for the Lego bricks to exit at a rate of 1-4 bricks per revolution. The shaft of the augur has a sprocket with a belt running down to a sprocket around the conveyor belt system's shaft, and is driven by it.

Color Sensor Assembly

The color sensor chip we used was Adafruit's TCS34725. This chip is hooked up to an Arduino Uno, in order to run the Arduino code. The sensor shines a bright, white light LED and reads the color reflected off of the surface. After reading a change in the color, the conveyor belt pauses briefly to allow the tray to rotate to the appropriate bin according to that color.

Color Bin

The bin that accepted the Lego bricks was split into six segments. There were four colors at the end of the design phase, Red, Green, Blue, and Miscellaneous. When the color sensor reads a change in color, the stepper motor underneath the assembly turns the entire tray to a specified position. The brick falls in, and the sensor reads the next color.

Testing

Consumer Testing

The best way to test the success of a product is to pit it against the very audience you have targeted and see if they can a) use it without explanation, b) use it without errors, and c) are entertained while using it. This is the very type of testing we incorporated during the end phase of our product's design. In the first video to the right, you can see a satisfied user operating the Sort n' Play during a rigorous test.

There are other videos of testing of different parts of the Lego sorter, such as the color sensor, the conveyor belt, the program that tells the system to delay, etc.